Unlock Manufacturing Digital Transformation with AIM Vision ERP

In today’s competitive landscape, achieving manufacturing digital transformation is essential for staying ahead. By leveraging tools that combine automation, real-time insights, and seamless integration, manufacturers can maximize efficiency and streamline operations. AIM Vision ERP, along with the AIM Mobility MES App and IGear, delivers the ultimate solution for transforming production processes.

Key Features of a Digital Transformation-Driven Manufacturing System

A fully integrated system is critical for achieving manufacturing digital transformation. AIM Vision ERP provides these essential features:

- Real-Time Insights: Gain immediate access to production and inventory data for informed decision-making.

- Automation: Eliminate manual processes by automating production tracking, scrap processing, and downtime reporting.

- Seamless Integration: Link AIM Vision ERP with mobility apps and Industry 4.0 tools like IGear for end-to-end connectivity.

How AIM Mobility MES App Enhances Manufacturing

The AIM Mobility MES App plays a central role in automating shop floor activities. Here’s how it works across key stages:

Start of Shift: Operator Onboarding

- Login Process: Operators log into the system using their employee badge and the AIM Mobility MES app. This ensures Poka-Yoke, which verifies proper operation sequences.

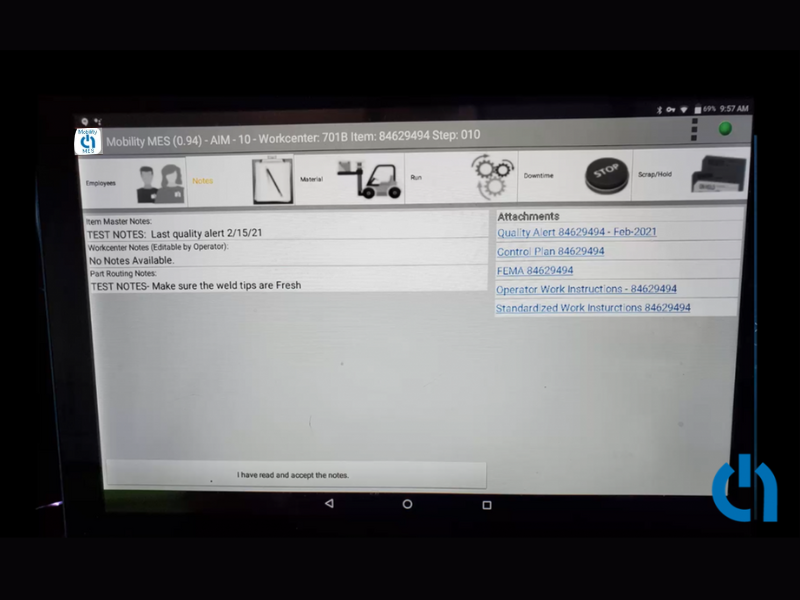

- Review Notes: Operators access detailed notes, including:

- Item Master Notes: Specific instructions for the product.

- Workcenter Notes: Shift-to-shift updates or supervisor instructions.

- Part Routing Notes: Information tied to the production process.

- Attachments: Hyperlinked documents like part drawings, FMEA documents, and quality alerts.

Once operators acknowledge the notes, they proceed to load component materials. In a full traceability environment, only BOM-approved lots can be loaded.

Running Production with Real-Time Monitoring

Tracking and Labeling

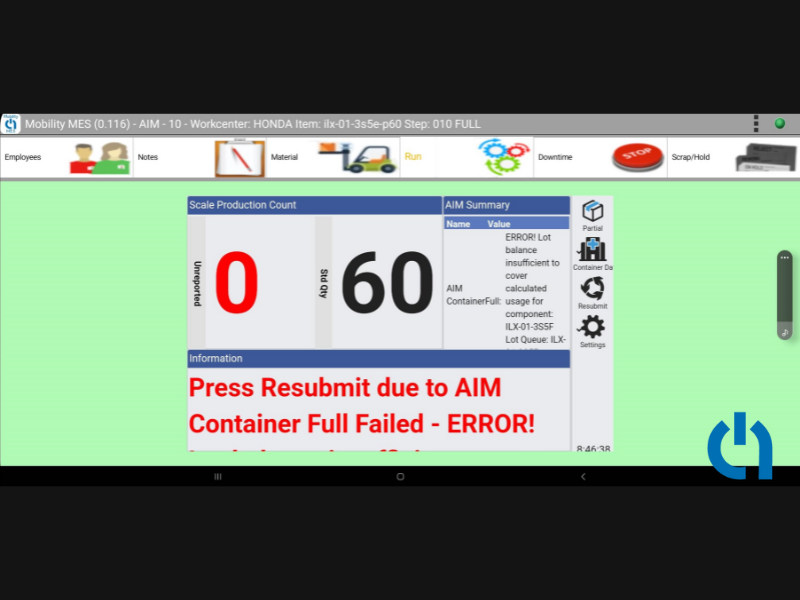

As production begins, the AIM Mobility MES app records every activity:

- Tracks material usage and updates inventory in real time.

- Triggers on-demand label printing once a container is full, ensuring accuracy and compliance.

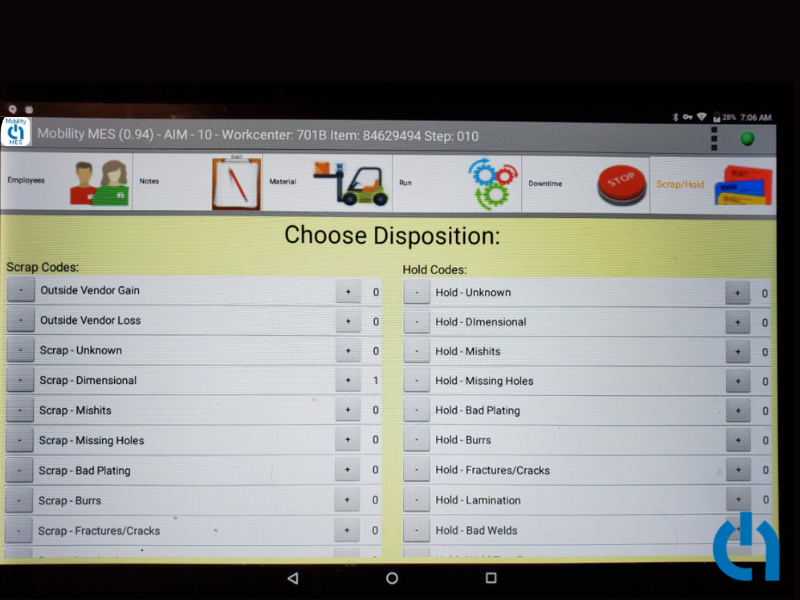

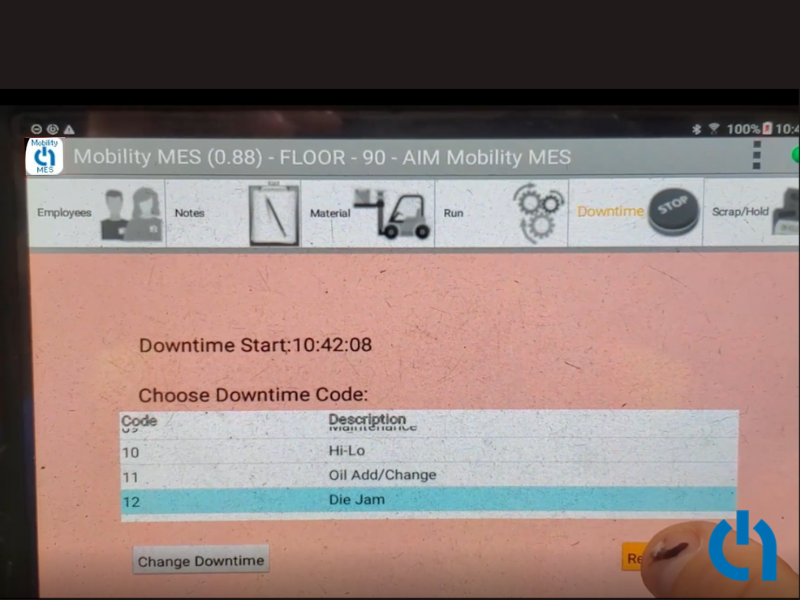

Managing Scrap and Downtime

- Scrap Recording: Operators use the app to log defective parts with specific reason codes.

- Downtime Management: If production halts, IGear automatically detects downtime and sends the signal to AIM Mobility MES. Operators input downtime reasons directly, and both systems sync the data.

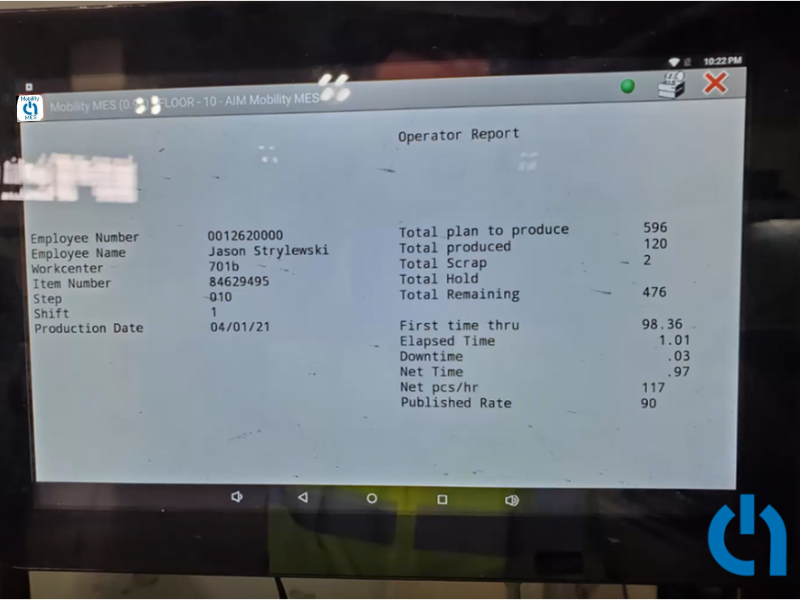

End of Shift Reporting

At the end of the shift, the AIM Mobility MES app simplifies reporting:

- Automatic Reports: The system generates daily operator reports with accurate production data.

- Supervisor Insights: Reports include total production, scrap quantities, and downtime analysis, reducing the need for manual tally sheets.

This automation not only saves time but also ensures precise and actionable data.

Driving Manufacturing Digital Transformation

The integration of AIM Vision ERP, AIM Mobility MES, and IGear exemplifies the power of manufacturing digital transformation. These tools provide manufacturers with:

- Macro-Level Reporting: AIM Vision ERP offers high-level insights into production and inventory trends.

- Micro-Level Monitoring: IGear captures detailed cycle data, providing granular views of workcenter performance.

- Comprehensive Dashboards: With iDashboard Data Analytics, supervisors can visualize real-time and historical data for continuous improvement.

Benefits of Manufacturing Digital Transformation

Investing in a digitally transformed manufacturing system offers significant advantages:

- Enhanced Efficiency: Automate repetitive tasks to save time and reduce errors.

- Improved Accuracy: Real-time data ensures accurate production and inventory tracking.

- Faster Decision-Making: Use dashboards and reports to identify trends and resolve issues quickly.

- Scalability: Deploy tools like AIM Mobility MES and IGear one machine at a time, scaling up as needed.

Interoperability in Industry 4.0

Interoperability is at the heart of manufacturing digital transformation. AIM Vision ERP, AIM Mobility MES, and IGear work seamlessly together to:

- Ensure smooth data exchange between machines, systems, and humans.

- Connect operators to real-time production data, fostering better communication.

- Provide insights that drive operational excellence and continuous improvement.

Transform Your Manufacturing Operations Today

Manufacturers can unlock new levels of efficiency and performance with AIM Vision ERP and its suite of productivity tools. Whether you’re looking to start small or scale up, our solutions are designed to support your journey toward manufacturing digital transformation.

Contact us today to learn more or schedule a demo. Let’s work together to modernize your shop floor and achieve operational excellence.

Explore Further

Discover how AIM Vision Mobility seamlessly integrates with the IGear scale to optimize manufacturing processes. This 2-minute video highlights how the integration automates production tracking, ensures accurate piece weight calculations, and improves packaging precision in real time.