Drive Manufacturing Transformation with Industry 4.0 Solutions

Empowering your shop floor with Industry 4.0 technologies helps manufacturers boost efficiency and profitability across the entire organization.

In a recent AIM Mobility MES implementation, we partnered with Accumine Technologies to integrate their SensorBot on machinery and equipment with the AIM Vision ERP system. AIM Mobility MES is a line side tablet app that provides real-time production data processing, printing of labels on demand, and operator efficiency tracking. Accumine’s wireless SensorBot monitors the machine or manual workstation and is able to provide real-time machine monitoring. Connecting these two technologies together provide a consistent and more flexible view of production and business operations.

Interoperability: How Systems, Humans and Factories Communicate with Each Other

Interoperability is the ability of computer systems to communicate and exchange data. When it comes to Industry 4.0, this includes the smart factory machines, and the humans who operate them. In order to appreciate the interoperability benefits of these solutions, let’s take a walk through a day in the life of an operator and explore the seamless connectivity of the AIM Vision ERP system to the AIM Mobility MES tablet apps to the Accumine Technologies SensorBots.

Start of Shift Activities

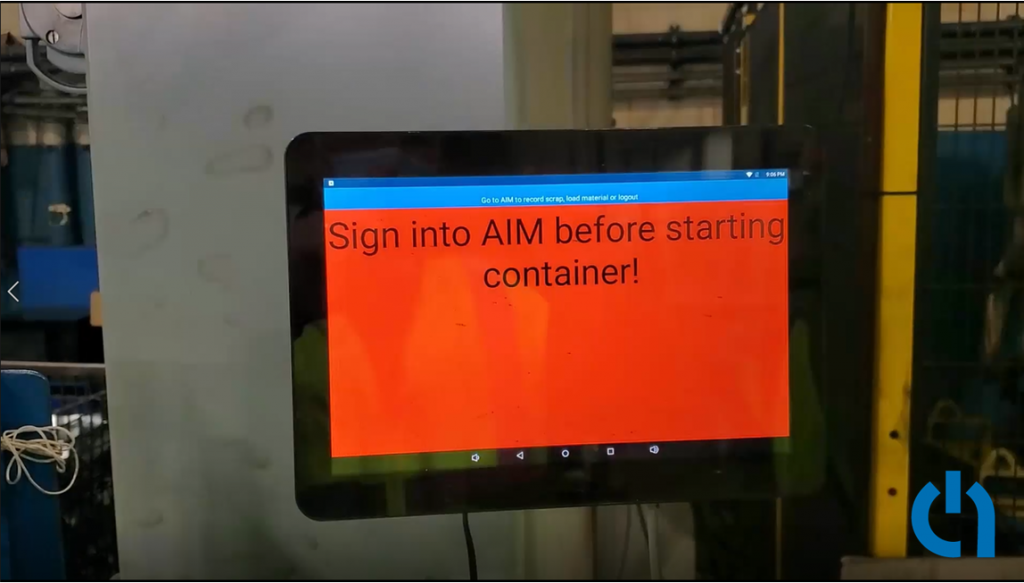

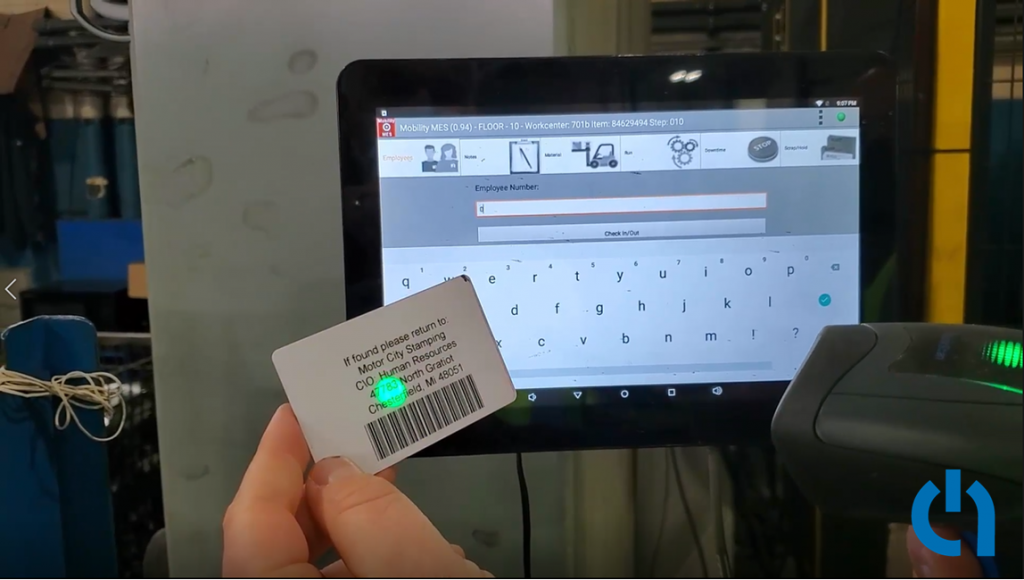

The operator will go to the machine or station which has a tablet loaded with AIM Mobility MES and the Accumine SensorBot. First, the operator must log into Accumine on the tablet. This process step is Poka-Yoke, to ensure proper order of operation.

Once logged into Accumine, the operator is notified to sign into AIM before starting production.

The operator scans their employee badge and logs into the work center using the AIM Mobility MES tablet app.

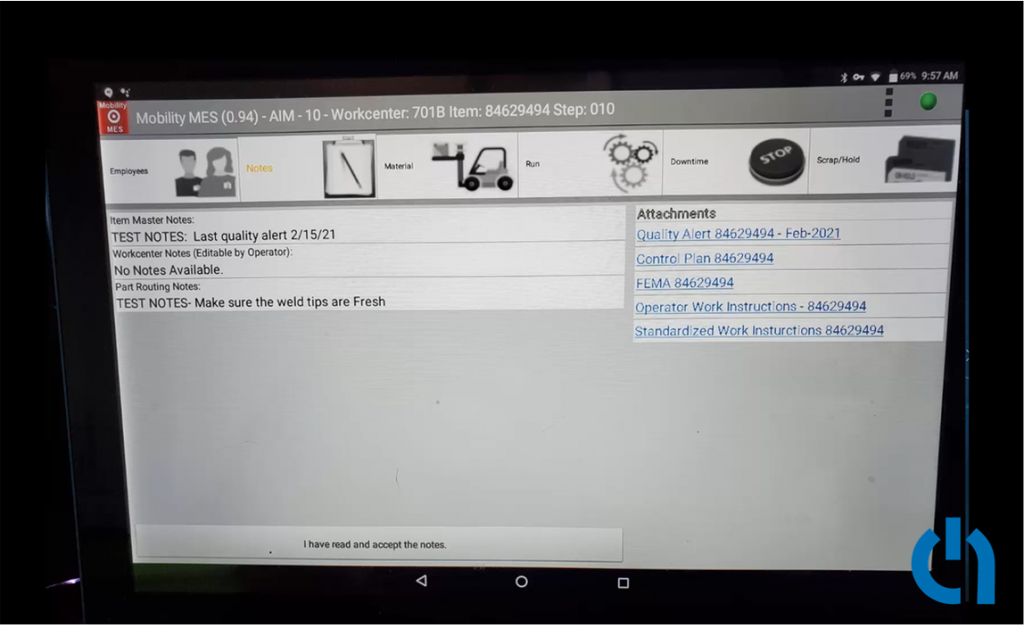

After scanning into the work center, the Operator is brought to the Notes screen. This screen contains four sets of notes, plus hyperlinked attachments.

- Item Master Notes are defined in the Item Master table and are specific to the item being produced. These are displayed for reference purposes.

- Workcenter Notes are can be used to provide instruction regarding the production job. These can be entered by an operator and are helpful when leaving notes about the machine from one shift to another. Alternately, these notes can be populated by the supervisor from the AIM Mobility Clipboard.

- Part Routing Notes are defined in the Part Routing table and are specific to the item being produced. These are displayed for reference purposes.

- Part/Step Notes are entered by the supervisor from the AIM Mobility Clipboard. These could be instructional in nature and may be used to indicate special notations related to this Part and Step.

- Attachments are linked to the Item Master in the AIM Vision ERP system, and are hyperlinked here for operator review. Examples include part drawings or prints, FMEA documents, control plans, quality alerts, operator work instruction, etcetera.

The operator will select the ‘I have read and accept the notes’ button to acknowledge they have reviewed the operations instructions.

Next, in a full lot traceability environment, the operator or material handler loads component material for the machine / job. This process step is also Poka-Yoke so that only lots of components from the current Bill of Material can be loaded into the work center. If the operator tries to load something else, the system will stop them.

As an aside, if operating in a full lot traceability environment within AIM Vision ERP, AIM Vision Is constantly recording the specific lot number of the component material lot. If component material lots are not loaded, or there is insufficient quantity to process a container full signal, then Accumine will request more material from AIM Mobility MES.

Running Production

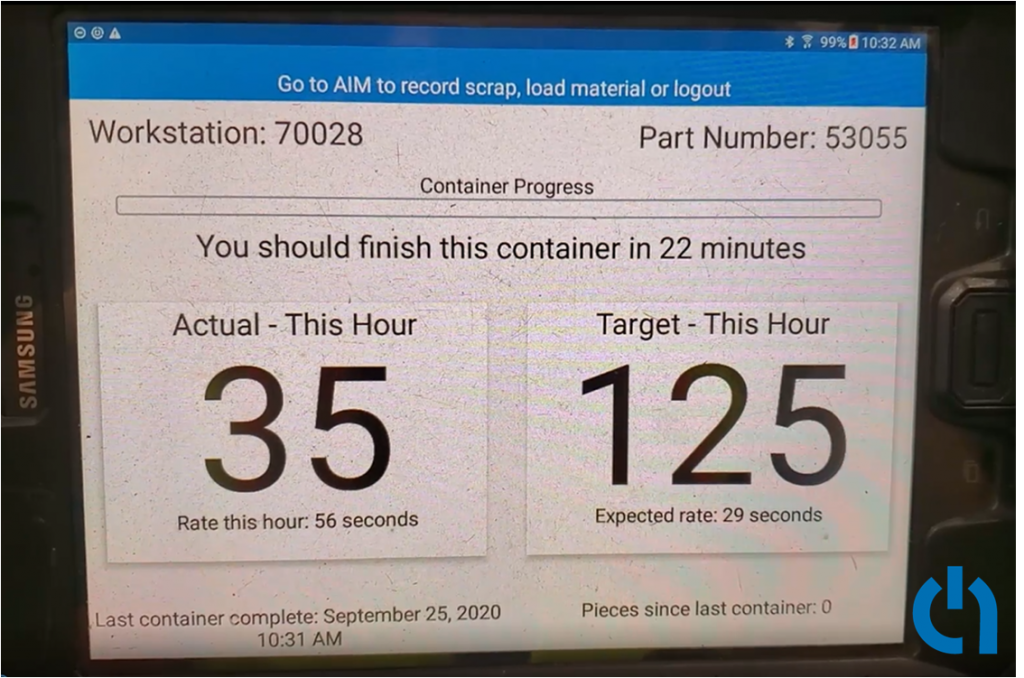

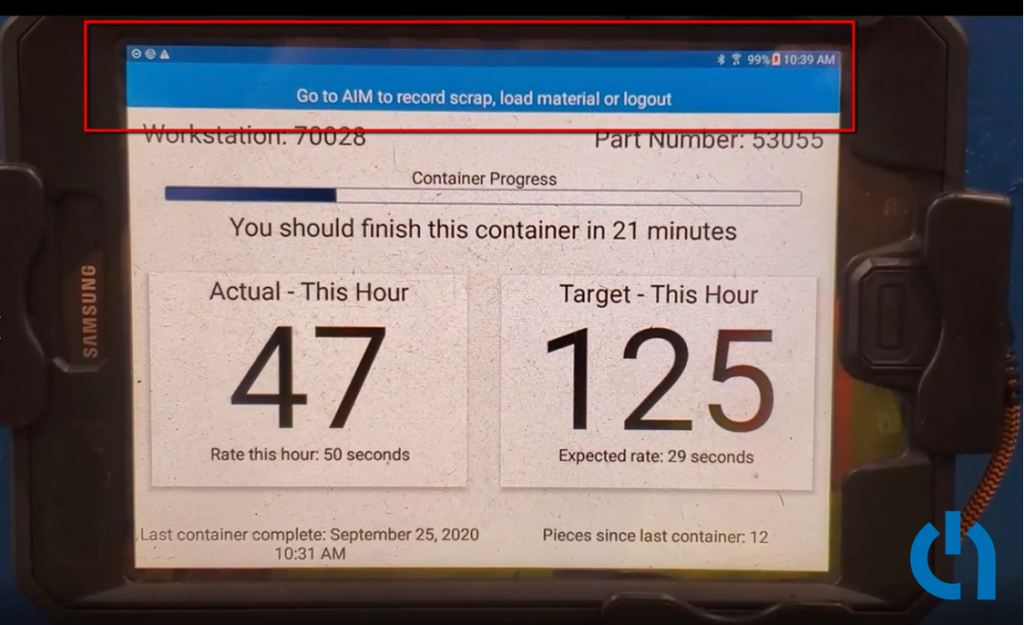

After logging in, reading notes and loading material, the Operator leaves the AIM Mobility MES Run screen and goes to Accumine.

The main Accumine screen shows the workstation, part number, current actual run rate of the cell as well as how long until a container is full and when the last container was finished.

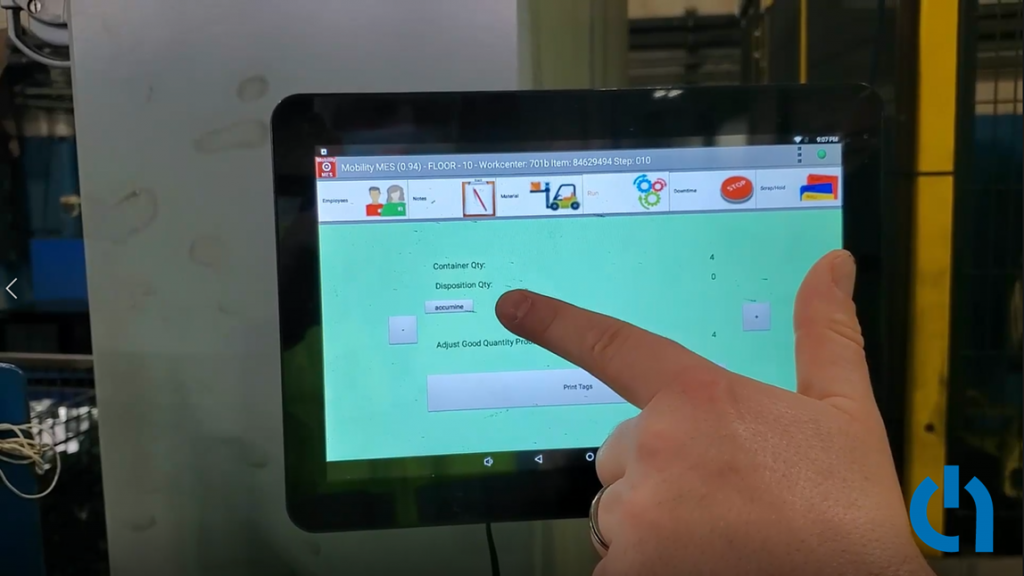

As a container is full, Accumine sends a signal to AIM to make a production transaction in the AIM Vision ERP system and generate a label. This solution is label on demand; a label is not created unless the machine cycles are counted.

NOTE: This label can be either an internal label or AIAG certified compliant shipping label.

Processing Scrap

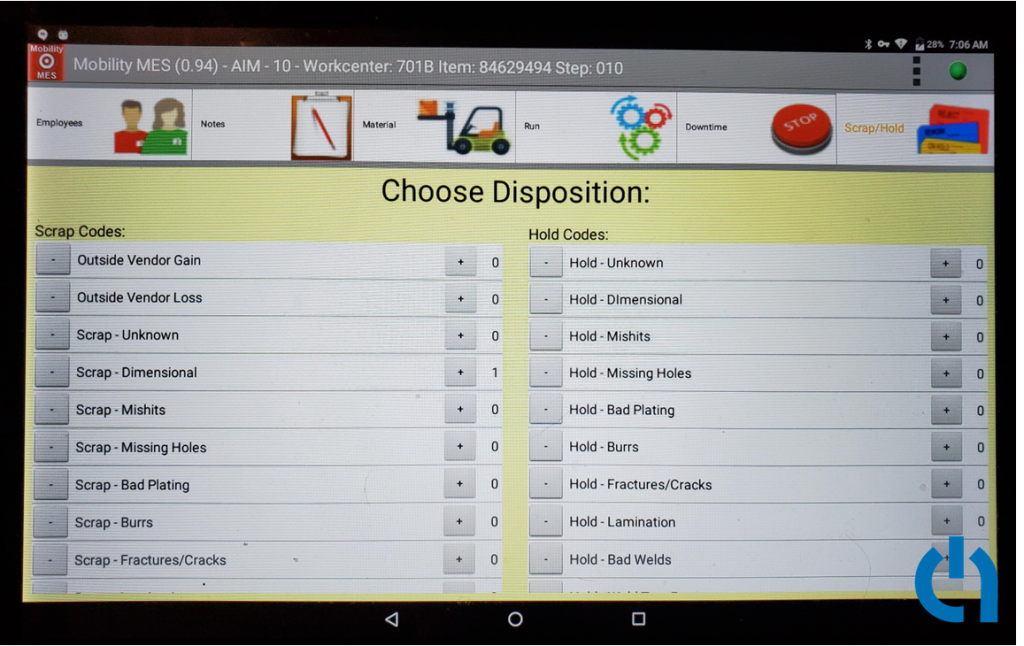

During regular shift operation, if the machine makes a scrap part, then the operator goes to AIM Mobility MES and records scrap quantity and scrap reason.

This data is relayed to Accumine and during next container full and print cycle, the scrap is recorded in the AIM Vision ERP.

NOTE: this same process would be true if the operator identifies a part which is suspect and needs to be placed on hold.

Processing Downtime

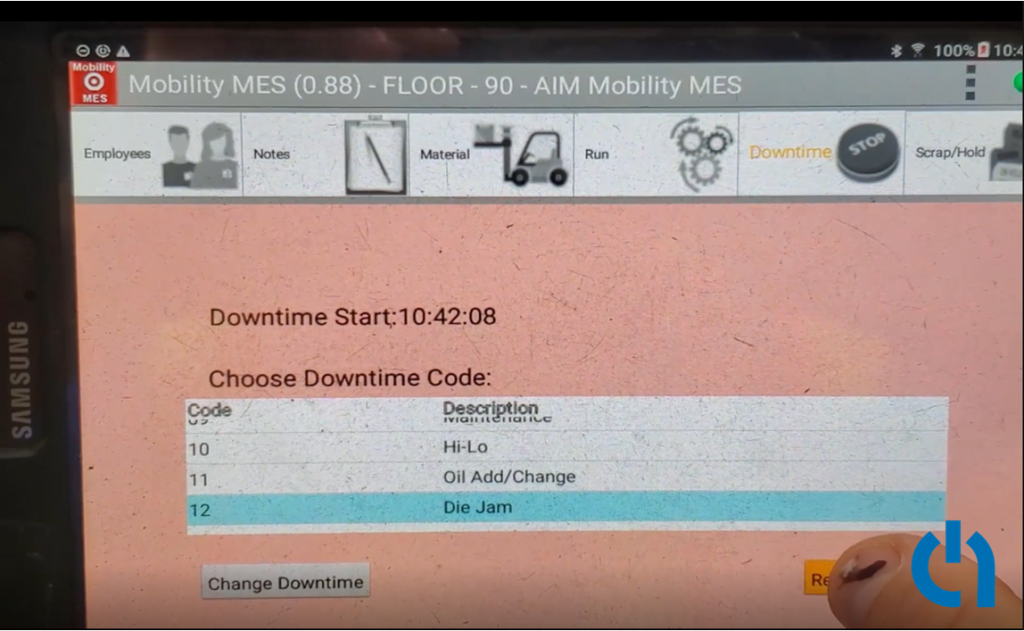

If the machine stops producing cycles, Accumine will know and begin recording downtime. Accumine will send this downtime signal to AIM Mobility MES so that AIM can also begin recording downtime.

The tablet will automatically be switched to AIM Mobility MES’s Downtime screen so that the user can select and input the reason for the downtime. This reason code will automatically be sent back to Accumine. Once the issue is resolved, the user Returns to the Run screen and accesses the Accumine screen to resume production.

End of Shift Activities

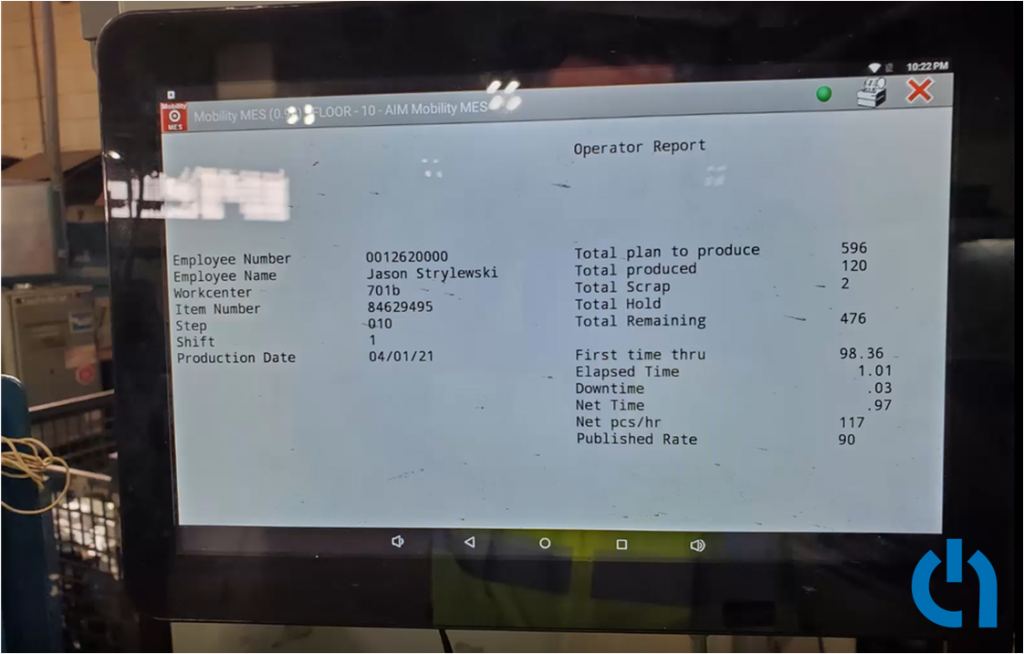

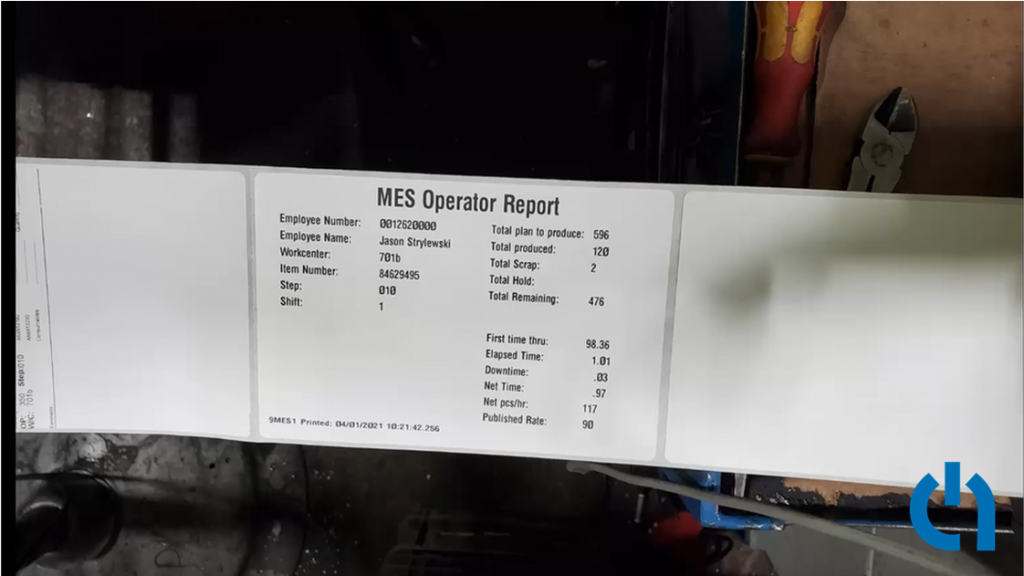

At the end of the shift, the operator accesses the AIM Mobility MES Employee screen to log out of the work center. Upon logout, AIM Mobility MES generates a daily operator report.

The AIM Mobility MES and Accumine solution automates the gathering of the operator ‘daily tally sheet’ information, which increases the accuracy of the data and eliminates the need for your operators to record these production details manually. In fact, this system generated report increases productivity and accuracy compared to the typical manual end of shift process that takes the operator away from production, and often has less than fully accurate data.

This MES Operator Report shows on the tablet, and can be printed and turned into the shift supervisor.

Gain Operational Intelligence

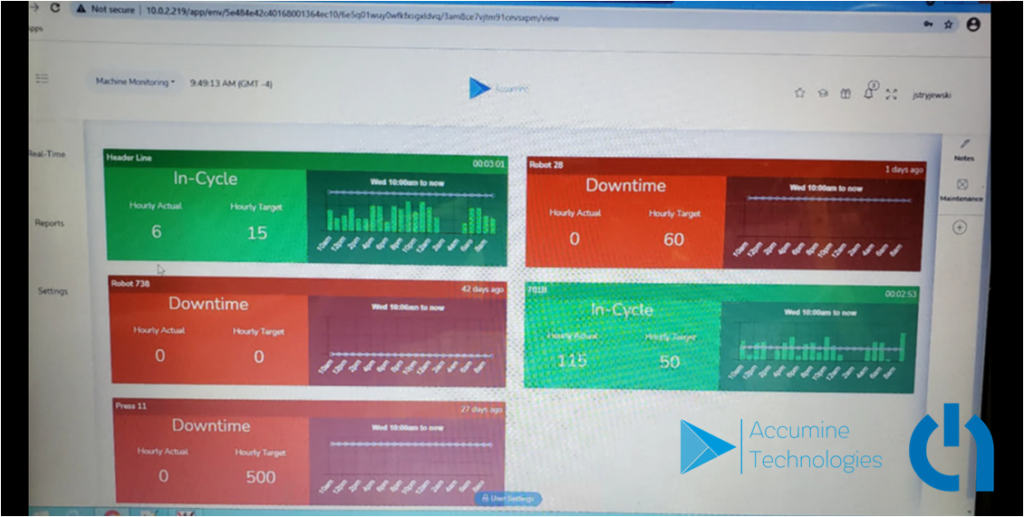

In this combined solution, users get real time insights from both the AIM Vision ERP system and Accumine Technologies that help them make better, faster decisions. While AIM focuses on macro production level reporting, Accumine is recording each cycle and every minute of the events of the work center.

Users can access all of AIM Vision ERP system production and inventory reports, but the data will become more complete and accurate.

AIM’ integrated iDashboard Data Analytics solution, uses AIM Vision ERP data, and therefore really comes to life when using AIM Mobility MES to record real time production data. In addition, Accumine provides another level of reporting within their solution that can be used by supervisors and managers to make timely production decisions.

Accumine has the ability to broadcast their reports on monitors within the plant to show real time production activities. These reports can also be used to show historical data over a date range and to identify positive and negative trends, supporting continuous improvement initiatives in your organization.

Manufacturing Transformation

Companies are able to maximize production performance with AIM Vision, AIM Mobility MES and Accumine Technologies SensorBot Industry 4.0 technologies. These solutions are flexible enough to be deployed one machine at a time, which allows you to start small, scale up, then take it forward to transform your entire plant.

Watch the AIM Mobility MES with Accumine Technologies promo video.

To see the ‘Day in the Life’ process, watch the AIM Mobility MES with Accumine Technologies integration video.

Next Steps

For more information, Contact Us, or Schedule a Demo.