AIM Mobility Clipboard App

The AIM Mobility Clipboard App, from AIM Vision ERP’s suite of manufacturing productivity apps, delivers workcenter and operator production intelligence with real-time entry and updating functions, all from a handheld tablet.

How the AIM Mobility Clipboard Works

The AIM Mobility Clipboard has two main purposes. Manufacturers use it to:

- Enter workcenter and operator efficiency data, including downtime and scrap, directly on the shop floor using a handheld tablet

- Edit production efficiency data from MES transactions or Excel spreadsheet uploads

![]()

Operators enter real-time production data in the AIM mobility clipboard app which works just like production post and entry processes but delivers the flexibility and mobility of a tablet.

Using the app, supervisors enter production efficiency data during the shift in real time, rather than waiting for a manager to enter the data at the end of the shift working from tally sheets.

The app offers defaults or “favorites” on the clipboard to identify employees, workcenter numbers and descriptions, and items and their steps by plant, shift and time. The app displays real-time intelligence.

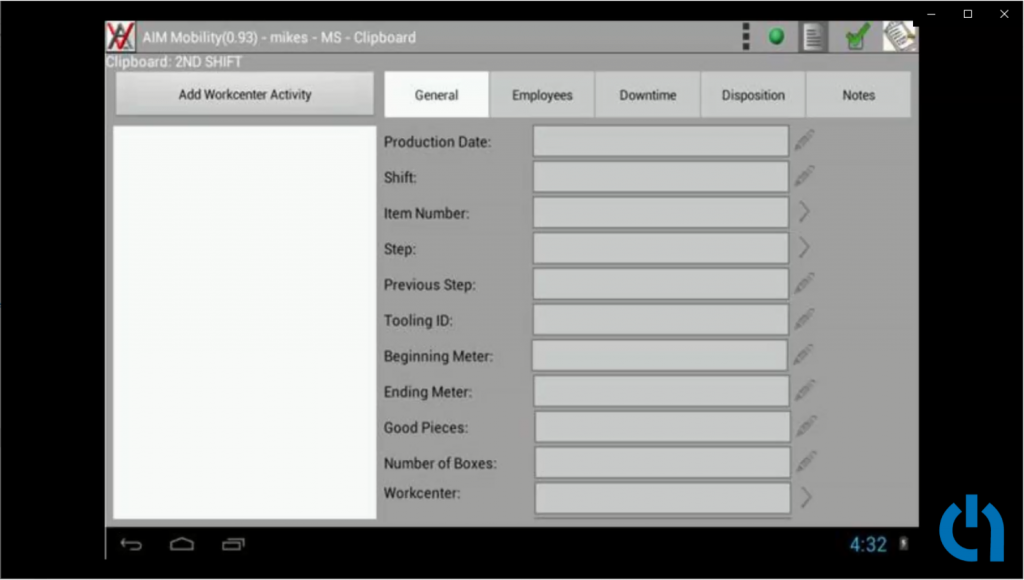

Entering Production Records

On the AIM Mobility Clipboard app, each production record is called a workcenter activity.

For each project number, the workcenter activity record identifies:

- Production date

- Shift number

- Item number

- Step

- Previous step

- Tooling ID

- Beginning and ending meter readings

- Quantity counts

- Workcenter hours

- Number of good pieces

- Number of boxes

The AIM Mobility Clipboard app associates these workcenter data points with employee time, downtime, and disposition information.

- Operators enter employee time as absolute time or as a percentage of the total workcenter time.

- The app identifies a variety of reason codes for downtime.

- Operators report item disposition against customized disposition codes, e.g., out of tolerance, and attach quantity and tag identifiers.

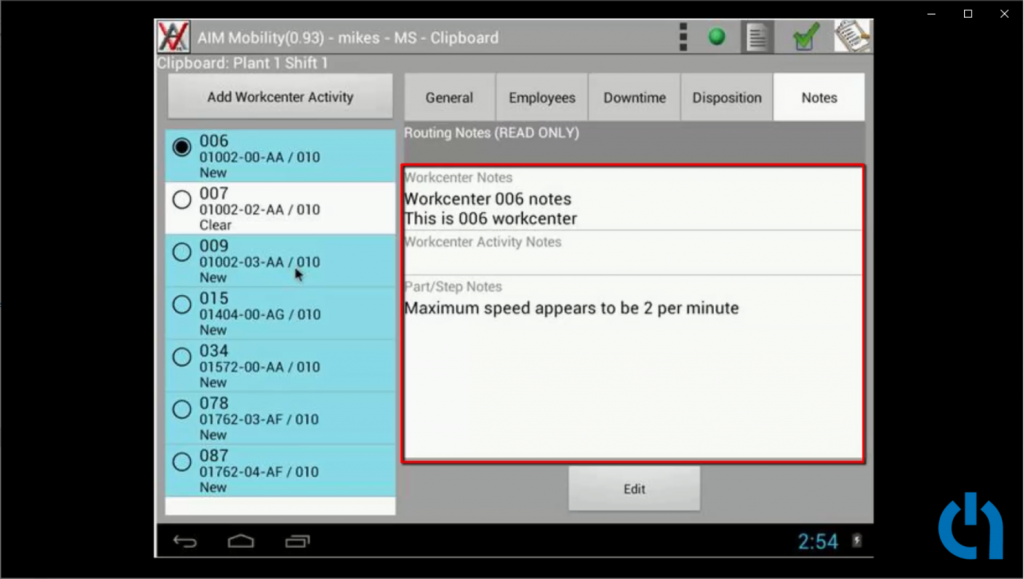

With the app, operators add notes to share intelligence with other operators and supervisors about conditions, parts, or steps.

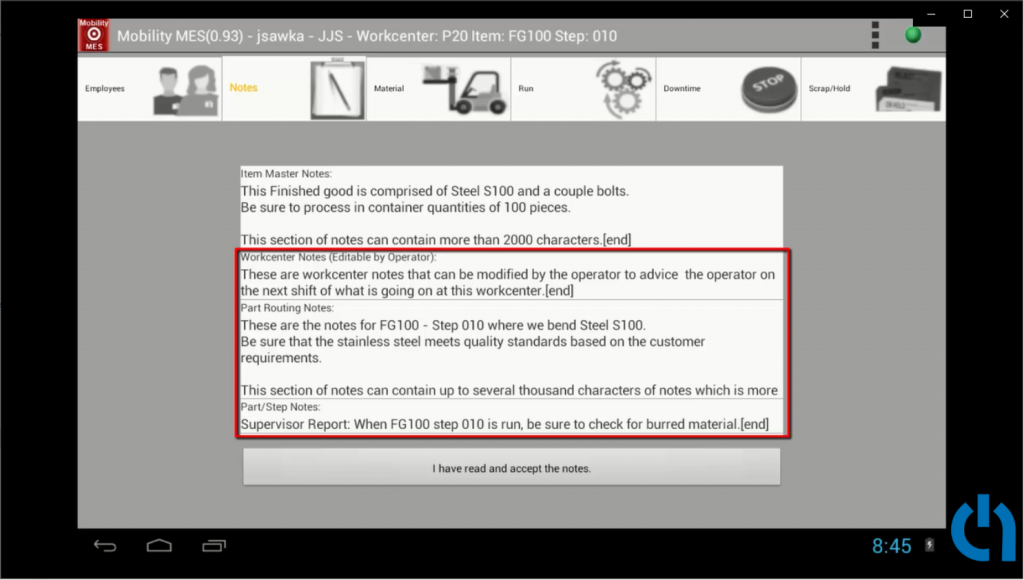

The workcenter record identifies four types of notes:

- Read-only routing notes

- Workcenter notes which appear whenever the workcenter is assigned to a workcenter activity

- Workcenter activity notes which are specific to the selected workcenter activity

- Part/step notes which appear when the operator selects an activity by item number and step

When users are also using the AIM Vision mobility MES app, operators see these notes when they log into the workcenter and must acknowledge reading them to proceed.

When using the AIM Mobility MES app, operators see all workcenter notes.

Importing Workcenter Activities

Operators import workcenter activities in two ways:

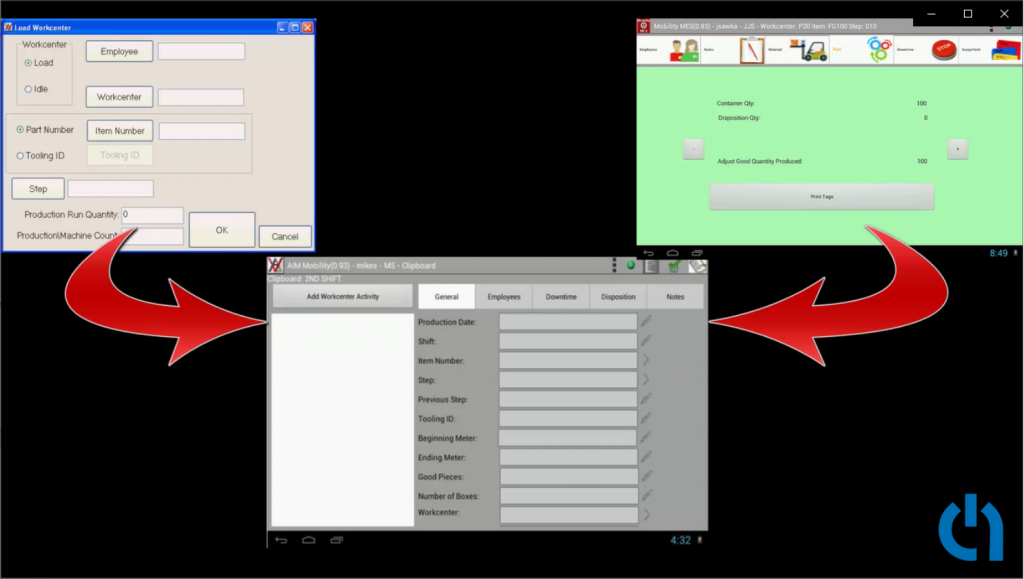

- Operators gather data from their MES system or the AIM mobility MES app and push it to the clipboard for editing. They use the clipboard app to edit the data before pushing it to AIM Vision ERP.

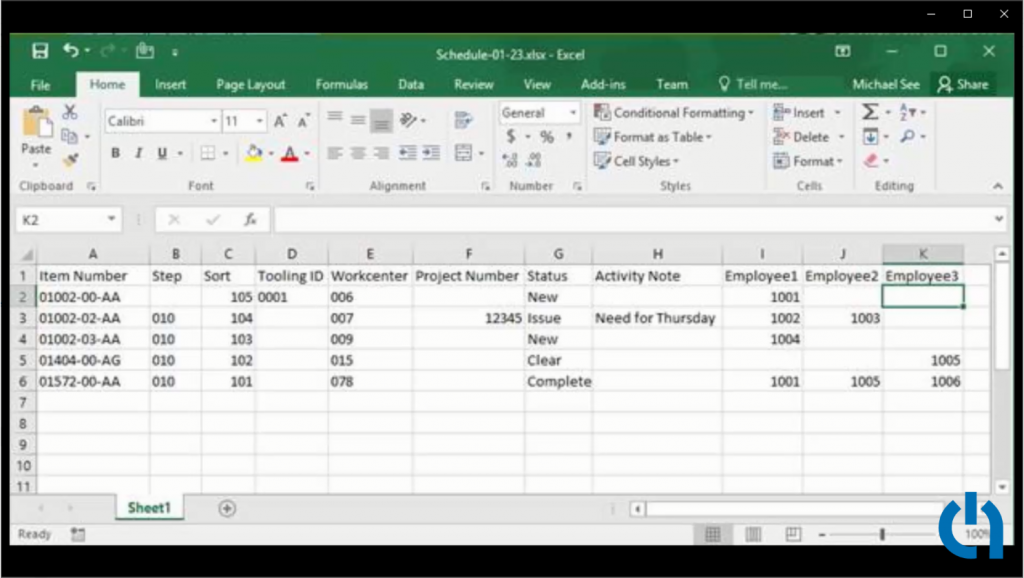

- Users can also import data from an Excel spreadsheet to consolidate workcenter activity and add production information into AIM Vision ERP.

It’s easy to push data into the clipboard app from mobility MES app.

Alternatively, users can upload data from a spreadsheet to the AIM Mobility Clipboard app.

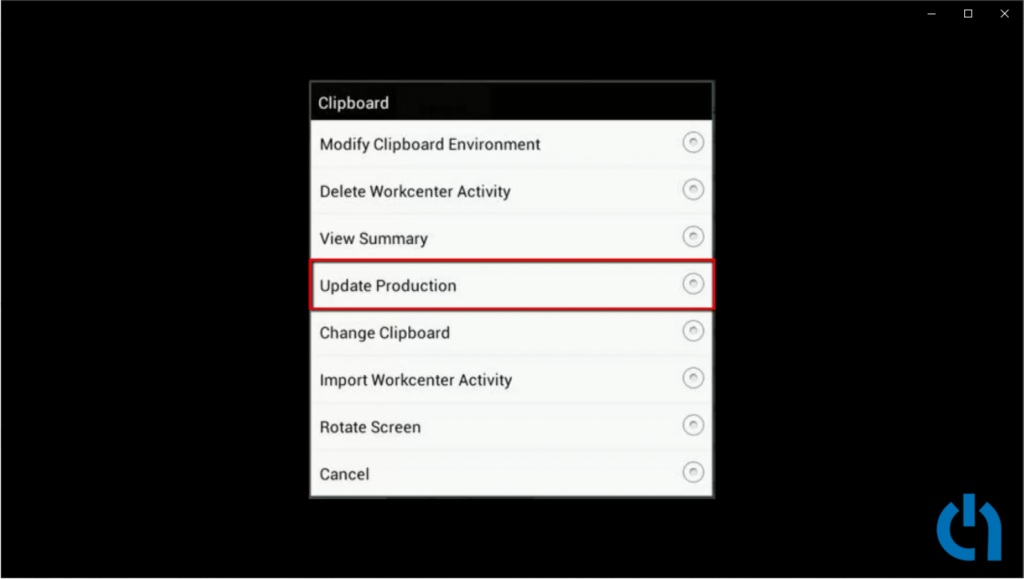

Operators need to update all production workcenter activity data, record by record, on the clipboard.

Clipboard Flexibility Options

The flexibility of the AIM Mobility Clipboard app means users can view and verify production data, record by record. Operators can set up clipboards to represent:

- Department

- Shift

- Zone

- Responsibilities

Watch the entire AIM Mobility clipboard app video.

Next Steps

If you’re ready to add flexibility and mobility to your activity center production data with the AIM Mobility Clipboard app, let’s talk. It’s time for real time production activity data.