Gain MES Efficiency with AIM Vision Mobility MES App

The AIM Mobility MES App is a game-changer for manufacturers looking to automate production tracking and reporting directly on the shop floor. As part of AIM’s suite of manufacturing productivity apps, the Mobility MES App integrates seamlessly with AIM Vision ERP, providing real-time production data and reporting. By using tablets and Wi-Fi-enabled printers, manufacturers can streamline operations, track efficiency, and gain actionable insights.

What Does the Mobility MES App Do?

The Mobility MES App automates key production functions, delivering:

- Time Clock Capabilities: Log employee activity with ease.

- Production Tracking: Collect data on material counts, downtime, and non-conforming parts.

- Label Printing: Print shipping or production labels directly from the shop floor.

- Real-Time Reporting: Backflush raw materials and maintain accurate inventory counts.

This app ensures that manufacturers have the tools they need to boost productivity and maintain accuracy at every stage of production.

How the Mobility MES App Works

The Mobility MES App simplifies three essential functions on the shop floor: time tracking, data collection, and workcenter load management.

1. Time Clock Functionality

Operators can log in and out using their employee number or by scanning their badge. This feature tracks employee activity and ensures accurate reporting of work hours.

2. Workcenter Data Collection

Once logged in, operators access the Workcenter Page, the central hub for data collection. This screen allows operators to:

- Read notes tailored to their workcenter, including instructions related to items, parts, or steps.

- Decide who can add or edit notes, ensuring only authorized updates.

- Track multiple employees at a single workcenter.

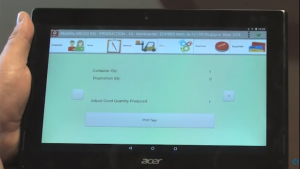

From there, operators move to the Run Screen, where they:

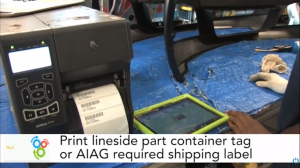

- Print lineside part container tags or AIAG shipping labels for full containers.

- Increase inventory counts and backflush raw materials automatically.

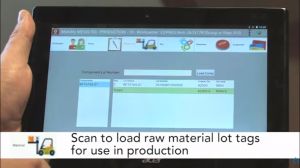

- Scan lot labels to add raw material to the production count.

3. Workcenter Load Management

The app simplifies changing from one part number to another using data from AIM Vision ERP’s Digital Whiteboard Scheduling. It provides:

- A clear view of workcenter status and jobs queued for production.

- Real-time tracking of scheduled vs. completed pieces.

- Insights into any downtime affecting the workcenter.

Tracking Downtime and Scrap

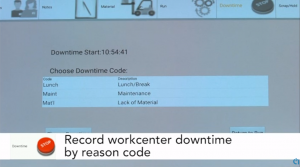

Downtime Reporting

Downtime is a critical production metric, and the Mobility MES App makes it easy to monitor. Operators can:

- Enter reasons for downtime, such as maintenance or material shortages.

- Start a system clock to track the duration of downtime.

- Use the Return to Run button to resume production once downtime ends.

Scrap and Non-Conforming Parts

The app’s Scrap/Hold feature allows operators to:

- Enter specific reason codes for scrap or hold, such as contamination or cracking.

- Update the disposition count/quantity directly on the Run Screen.

- Print labels for good and scrap parts, ensuring accurate backflushing of materials.

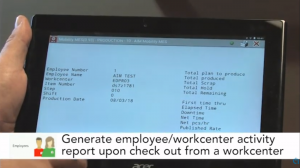

Real-Time Reporting for End-of-Shift Insights

At the end of a shift, operators log out of the Mobility MES App. The system automatically confirms production counts by item number and operator. Key metrics in the Workcenter Operator Report include:

- Total items produced

- Total scrap or hold quantities

- Total and net production time

- Downtime duration

This level of detail provides managers with a clear view of production efficiency and areas for improvement.

Key Benefits of the Mobility MES App

The Mobility MES App transforms shop floor operations by providing:

- Enhanced Efficiency: Automate tasks like material tracking, downtime reporting, and label printing.

- Improved Accuracy: Eliminate manual errors with real-time data collection and reporting.

- Actionable Insights: Gain deeper visibility into production metrics and operator performance.

- Streamlined Workflows: Manage production loads seamlessly with integration into AIM Vision ERP.

Watch a demo video:

Take the Next Step

Ready to transform how you track and report production? The AIM Mobility MES App offers manufacturers the tools they need for accurate, real-time intelligence on shop floor production. Contact us today to learn more or schedule a demo. It’s time to unlock efficiency with the Mobility MES App.